While the use of sand and cement render these days is less common compared to more modern renders, there is no denying the massive impact this mixture has had on society and the development of the world. Ancient Roman homes, English village houses, rows of properties on Greek islands, and so many more properties benefit from the humble mix of cement and sand as the top layers of their property.

If you want to learn more about this hugely popular render, how it ranks alongside more modern mixes and options, and why lime is important, we can help.

WeDoRender are rendering specialists in Leyburn, and we are pleased to say we know the pros and cons of sand and cement for your external walls of your Leyburn home.

Most renders consist of a mix of sand, cement and lime with water. The most predominant component is sand, often featuring six parts sand to one part cement and one part lime, following the 6:1:1 ratio. This is the correct mix for most users, although some professionals use a 4:1:1 ratio, albeit more for internal as opposed to outside walls.

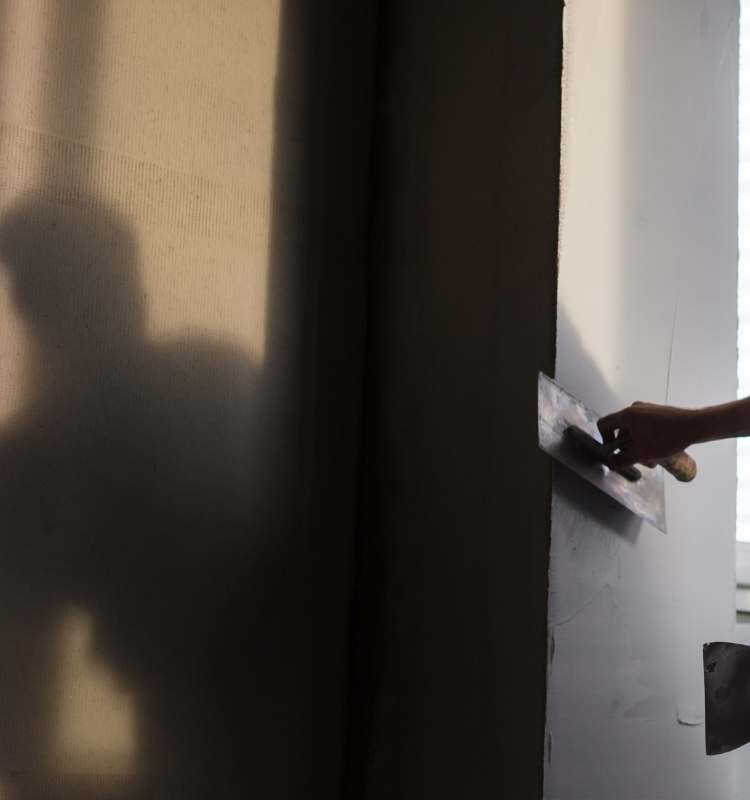

Render is most commonly mixed in a cement mixer, which helps to create a thin coat and smooth layer. This is applied in coats featuring the bottom and top layers. To create an authentic finish on external walls, run a brush over the mixture, creating a textured style.

You might be surprised to learn there are different types of sand, and some are more effective and productive than other types.

For instance, you shouldn’t use building sand as the lead component in render. If you’re keen to use this material, you can apply a minor amount when mixing the scratch coat. However, building sand shouldn’t be used with your top coat.

The best sand, due to their strength, is sharp sand and plastering sand, and both work well with cement render, creating a straight edge at your home. Of course, this render doesn't only work well with bricks, it is suitable for concrete blocks too, if this is relevant.

Lime is used to increase elasticity in the mixture. This is essential as the added movement allows expansion and contraction, reducing the likelihood of the render cracking.

Lime is helpful as it has self-curing qualities, and it self-renders. This is useful as it ensures moisture and vapour can move from inside to out. Walls need to breathe, and if they can’t, dampness problems will occur inside the property.

This is also beneficial as hydrated lime makes the mix creamier, essential in developing a smooth and flat finish. If you desire a straight edge with your render, the lime plays a massive part in this.

Before you move on, be on the lookout for unmixed sand in the sand and cement render, as this can compromise the quality of the finish.

One of the most impressive aspects of sand and cement renders is the variety of finishes available for your exterior walls, creating great aesthetic appeal with the finished job.

A textured finish, achievable by adding coarse sand, adds a great deal of texture to the final appearance on the wall.

A sponge finish, achieved with a moist or slightly damp sponge creates a unique texture that stands out from the crowd on your wall, for all the right reasons.

A bagged or patterned finish occurs when a Hessian bag with a ball in it is rolled across the damp surface, creating a unique finish.

A trowel finish is perfect for those seeking a smooth and fine finish, using a wooden float, skimming the surface of the top coat.

A roughcast finish is a popular choice, and this comes through flicking mix or crushed aggregate onto the wall.

A pebbledash finish is similar to roughcast but the pebbles and aggregate aren’t added to the render mix, they feature later in the process.

As you see from this extensive list, traditional renders are the platform for some not-so-traditional styles and patterns. If you are curious to see what you can achieve with traditional renders, even with a thin coat, call on WeDoRender.

Most render specialists and experts believe a base coat is essential, and we are no different. A scratch coat is a thin coat of mortar, plaster or render, and it should be 5mm thick or less. Apply this first coat to the surface wall, and then use a comb to create grooves before the mixture dries.

The purpose of the grooves is to ensure each subsequent layer has something to grip to. The tracks create a bond, and when the mix dries, there is a stable and robust bond.

If there isn’t a secure bond, there is a high chance the render slips from the wall as it cures. When it's dry, it is more likely to have gaps between the render and wall surface, making hairline cracks and gaps more likely.

Before too long, the coat falls off, exposing the bare brick wall beneath the render. So, a base coat is essential, and you must apply it correctly.

WeDoRender knows how to apply a first coat render properly, and we can manage this task for you and all render duties. Contact us to discuss your needs or to arrange an appointment.

As you have a few options to consider with render, you need to know how to differentiate between your options. There are some things you need to focus on, including:

While this mixture represents a traditional render form, modern renders offer a more exciting range of opportunities and benefits.

Acrylic render is one such option; an immediate advantage over traditional rendering is that you don’t need to paint it. Knowing you can blend any colour, hue or shade you want into the rendering, and it comes out exactly as you hoped is a great comfort.

If you apply a colour scheme to your render, be sure you check out local homes. You don't want to stand out for all the wrong reasons. However, a great looking house makes many people feel at home, and you have the freedom to beautify your home as you see it, especially with coloured render options.

If you want the render to have a specific colour, you must paint it on the walls. This is time-consuming, and not everyone is great at painting. Hiring a professional to paint your walls increases the cost of caring for your home.

This increase negates the benefit of this mix being a more affordable option, so you need to consider whether this is the best choice for your needs.

If the best render system for your wall is one that has a colour pre-mixed, cement renders might not be your ideal solution.

Another powerful feature of acrylic render over the traditional rendering is how long it takes to dry. Traditional cement render can take more than a month to fully dry, which is a very long time. With acrylic rendering, the render dries in a few days, allowing you to move on to your next task.

Acrylic render lacks the same breathability components as silicone rendering, and it isn’t as effective at self-cleaning at that activity either. However, these are two slight drawbacks, and there are many reasons why acrylic and acrylic render is a hugely popular choice for homeowners.

With a traditional render applied well, you can enjoy a dependable surface for decades. However, you should maintain it regularly, giving it special attention every five years or so. You should also look out for bubbles or cracks, which need to be dealt with.

More contemporary rendering can last for 30 years, but homeowners need to balance out the different cost and return from a rendering project. When you search for a solution less susceptible to cracks, a rendered finish with lime is a great starting point. Traditional render performs well, but more modern renders might be better for your wall.

Many factors influence the price of render, including materials such as sharp sand, labour, equipment, location and size of project. We have a good relationship with many builders merchants, which ensures we access the best materials and different tools for a fair price.

This includes leading brand names, including K Rend or DIY Doctor. To take the stress out of all render work, including applying render and making sure your next coat is the right coat, call on us for a smooth finish every time.

Checkatrade, as of the summer of 2022, states an average of £2,835 - £5,670 for a three-bedroom semi-detached house. This comes from a price of between £31 and £63 per square metre for traditional render. For a bungalow, the same source states an average of £1,575 to £3,150 for reliable rendering work.

WeDoRender is a specialist render firm, and we use specialist equipment. Proper use of a rendering float, a rendering comb and cement mortar speeds up the process without compromising quality, even for a thin coat of render. Using specialist machinery increases the cost of work, but it helps deliver the best results, and we have a skilled and experienced team.

Another great tool beloved by professionals is a spot board, which helps create the best mix, by keeping the substance wet without having to make too many trips back to the mixer.

We are here to assist you if you’re looking for the best results when rendering your home, even with traditional render.

For the best looking and dependable Leyburn house, you need to render your home properly. Applying the right mix to a brick wall seems easy, but it is often far from it. If you have large areas to cover it, the thought of cracks appearing due to poor work is off-putting.

To ensure your Leyburn house looks great and stands up to all conditions, contact WeDoRender. We are rendering specialists, from adding lime to a mix to the final rendered finish. To enjoy a fine and smooth wall, make sure you contact us, and we will be more than happy to assist you. Whether you want to arrange an appointment or you need additional information, contact us today.

Most renders are composed of sand, water, cement, and lime. The usual proportions for this mix are 6 parts sand, 1 part cement, and 1 part lime (6:1:1). There is no specific type of cement that should be used; any type will suffice.

Sand and cement render may only last a few years because it has no give and as the building expands and contracts with temperature it can cause movement.

If the water evaporates from the material too rapidly, the render does not have enough time to adhere correctly, and the surface colour can appear uneven and discoloured. A render that has dried out too quickly is a dehydrated, fragile surface, and cracking is unavoidable.

Then you can apply a particular modified sand and cement render that prevents moisture and salts from passing through. This procedure protects your new surface and finishes both during and after drying.